- Climate starts with SEA

- Posts

- 🏭 [#12] Industrial Decarbonization: Building Greener

🏭 [#12] Industrial Decarbonization: Building Greener

🏛️ Coming up with a concrete plan

Hello! Halo! Kumusta! Xin chào! สวัสดี! မင်္ဂလာပါ! ជំរាបសួរ! ສະບາຍດີ!

🦸 Superman is known as the “man of steel” and arguably the strongest superhero in the DC universe. But did you know that according to research from ETH Zurich: bamboo actually outperforms steel in terms of tensile strength on a per weight basis?

🎍 Perhaps Superman should actually be called “Bambooman” instead!

In this issue we’ll be discussing how heavy industries fabricating materials like steel are contributing to the climate crisis in Southeast Asia…

🏭 What’s the deal with industrial decarbonization?

As mentioned on our 4th issue, which covers sustainable production, how we make things matters for the climate: from consumer materials such as plastic, cotton and leather to industrial materials like steel, concrete, and glass, how we make things contributes over 20% to global greenhouse gas emissions (GHG) annually (Drawdown, 2022).

📊 The biggest contributors to emissions related to industry are steel and cement fabrication. Producing both materials are energy-intensive processes, relying heavily on fossil fuels; this is especially true Southeast Asia, which often uses outdated technology (UNIDO, 2022).

🤯 Because both steel and cement make up roughly 15% of the global carbon dioxide equivalent (CO2e) emissions respectively, it would be equal to the rank of the world’s fourth largest greenhouse gas (GHG) emitter, just behind China, the US, and India (NRDC, 2022). Let’s break this down:

⚙️Steel: every tonne of steel produced leads to the emissions of nearly 2 tonnes of CO2e emissions. With 1.9 billion tonnes (Bt) of steel produced in 2020, the total direct emissions were roughly 3.6 Bt CO2e emissions, which represents about 8% of global anthropogenic CO2e emissions (World Steel Association, 2021). Moreover, Southeast Asia's steel industry is expanding, driven not just by construction and manufacturing demands, but also ironically electric vehicles and wind turbines (SEAISI, 2023).

⚱️Cement: every tonne of cement produced leads to around 0.6 tonnes of CO2e emissions (IEA, 2023). With over 4 Bt of cement produced in 2020 (Nature, 2023) this translates to almost 3 Bt CO2e, accounting for approximately 7% of global CO2e emissions (UNECE, 2022). Global demand for cement is expected to increase roughly 20% by around 2050 and 2 out of the 5 top cement producers in the world are ASEAN countries (Vietnam & Indonesia) so it’s considered a major industrial commodity with strong interests from a political economy perspective (The Diplomat, 2023).

🌫️ Other GHGs beyond CO2

You may have noticed that we used the unit notation of CO2e rather than just CO2. Why is this? Well, emissions related to industrial production are not just limited to CO2, but also include other GHGs, which are converted back to the common unit measure of CO2 in terms of their global warming potential (GWP). Let’s highlight a couple of them below (note: you may recognize some of them from our past issues):

Methane (CH4)

Methane emissions primarily arise from the combustion of fossil fuels. Methane has a higher short-term GWP compared to CO2. Over a 20-year period, methane is estimated to be approximately 84-87 times more potent than CO2 (NASA, 2016).Nitrous Oxide (N2O)

N2O emissions come from the use of nitrogen-containing compounds from fuels, as well as high-temperature processes. N2O has a much higher GWP than CO2, estimated to be around 265-298 times more potent over a 20-year period (ScienceDirect, 2017).

🛣️ Pathway to decarbonizing industry

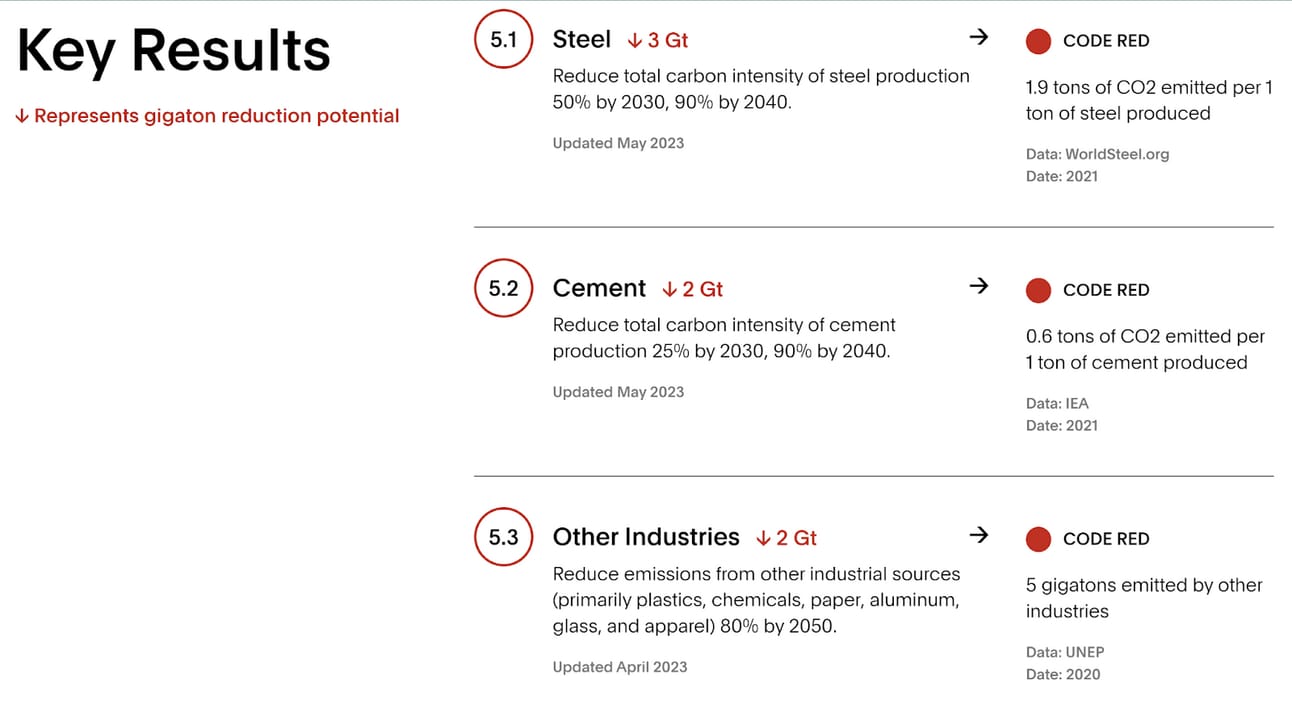

According to John Doerr’s Speed & Scale, there is a pathway to reduce the current 12 Gt of material production related emissions to 4 Gt by 2050.

🛠️ Technical solutions for decarbonizing heavy industries

⚙️ Steel

As you can see from the diagram above, there are a few different techniques for reducing the emissions factor of steelmaking. We are going to highlight 2 in particular…

🟢 Green Hydrogen

Green hydrogen is produced using renewable energy sources through a process called electrolysis. Renewable electricity is used to split water into its two main components: hydrogen and oxygen. This process—called electrolysis—occurs in an electrolyzer. In steelmaking, reducing agents are used to remove oxygen from iron ores to produce iron, a crucial step in steel production. Traditionally, coal or coke (derived from coal) is used as a reducing agent in blast furnaces, emitting large amounts of CO2. Leveraging green hydrogen in steel production has the potential to reduce CO2e emissions by 20% (McKinsey, 2020).

⚡ Electric Arc Furnaces (EAFs)

🔥 An EAF is a type of melting furnace used for producing steel through the melting of raw scrap metal through electrical energy. This method has a carbon intensity that is approximately 75% lower than a traditional blast furnace, producing less CO2 emissions and making it more sustainable and environmentally friendly (Recycling Today, 2022).

⚱️Cement

🔒 Carbon Capture, Utilization, and Storage (CCUS)

🌫️ CCUS describes a set of technologies to decarbonize heavy industries—including both steel & cement—by preventing the carbon from entering the atmosphere. Using this technique, CO2 can be captured and stored in geological formations underground. Moreover, the captured CO2 can also be used for downstream products such as synthetic fuels for transport, or chemical products (Cembureau).

Alternative Binders

📂 No, a “binder” doesn’t refer to your high school accessory for organizing your papers—in this case it refers to the chemical agents that hold concrete together. Concrete is a composite compound that consists of cement, water and aggregates (i.e. sand & gravel), in which cement typically serves as the binding agent. Alternative binders can reduce the carbon footprint 👣 of concrete and include innovations such as:

AshCrete: a concrete alternative that uses fly ash 🪰—a by-product of burning coal—instead of traditional cement as a binder. While it’s not an ideal long-term solution, it’s a decent transition solution to leverage waste materials from coal combustion, which is a major industry in Southeast Asia, especially Indonesia (Rethinking the Future, 2020).

Ferrock: a new material being researched that uses recycled materials from the steel industry such as steel dust, so it’s a nice complement to the material discussed in the previous section. In theory, it can be used to create a building material that is even stronger than concrete (Constro Facilitator, 2020).

Bamboo reinforced concrete: according to preliminary research on concrete that has been reinforced with bamboo, the flexural strength can actually outperform steel reinforced concrete by 6.5% (Science Direct, 2017). We’ll spend a bit more time discussing bamboo during our interview with Arief, the founder of Indobamboo.

While the above solutions are promising, it’s important to keep in mind that the pathway for decarbonizing heavy industry rests upon several considerations:

💰Appropriate funding given high capital expenditures

📱Viability for scaling novel technologies

🧾Appropriate regulatory support

🔽Substitutes for greener materials (e.g. bamboo)

📚 Want to learn more about this topic?

“Hydrogen sparks change for the future of green steel production” from ING

“Helping Countries Manage Growing Industrial Pollution Problems” from Development Asia

📢 Shout-out to Society of Renewable Energy (SRE)!

SRE Indonesia is the country’s largest youth-led organization focused on the energy transition, offering capacity building through education and hands-on projects. They serve as a bridge between the industry, government, and youth through their membership of 3000+ spread across 47 Indonesian universities.

SRE’s achievements include official delegation to COP (26-28), co-organizers of the 1st Southeast Asia Youth Energy Forum, knowledge partner for the G20 Energy Transition Working Group, and a national record for the most youth participants in a renewable energy webinar.

🤝 As you may have noticed, we actually co-authored this issue with Rauf Usman, the chairperson of SRE, given their relevance to this topic. An op-ed on industrial decarbonization for Indonesia—written by both him and Aufar Satria, their commissioner—was recently published by Eco-Business.

🗞️ Recent News

👍🏻 Good News

🚀 Indonesia launches first carbon storage project in West Papua (Reuters, 24 November 2023)

🌱 Indonesia’s PLN launches 21 green hydrogen plants, the highest in Southeast Asia (Tempo, 21 November 2023)

0️⃣ Indonesian steel giant Gunung Raja Paksi is going net-zero (Eco-Business, 2 April 2023)

👎🏻 Bad News

🤬 Indonesian islanders file climate complaints against cement giant Holcim (Straits Times, 2 February 2023)

⚒️ Obstacles to Decarbonisation in Southeast Asia (Fulcrum, 5 April 2023)

🛞 Thai cement production needs to reduce its carbon emissions (Bangkok Post, 29 March 2023)

📢 Other Voices

🎍 “Can bamboo be big in construction?” by Suzanne Bearne (BBC, 21 November 2023)

♻️ “Southeast Asia’s steelmakers face long road to ‘green steel’ – GRP sustainability chief” by Jessica Zong (Fastmarkets, 10 July 2023)

🎙️ Interview with Arief of Indobamboo

Bamboo requires not only the ecological level, but also the interwoven human dynamic at a social level, to value it. We believe that only by coupling the environmental solution with both economic and cultural incentives can we build towards a sustainable, systems-level solution.

💡 Why were you initially inspired to start working with bamboo materials as an environmentally-friendly solution?

💚 I actually started working with bamboo from the perspective of a foundation, working from an environmental and community development angle with my late mother, Linda Garland.

The business model emerged when we understood that profitability was going to drive a sustainable bamboo sector in Indonesia, not philanthropy—we learned a lot from the Chinese. Thus, Indobamboo was designed to be the private, for-profit partner that would accept all of the bamboo foundation’s values and principles as core to its practice.

🛠️ How exactly is Indobamboo tackling this?

🎍 Bamboo requires not only the ecological level, but also the interwoven human dynamic at a social level, to value it. We believe that only by coupling the environmental solution with both economic and cultural incentives can we build towards a sustainable, systems-level solution. Moreover, the key to sustainable harvesting is also understanding how to integrate intercropping bamboo alongside other valuable commodities such as coffee, banana, clove, etc. Doing this altogether reduces the cost of logistics and harvesting, creating a holistic solution.

😲 What is a misconception or surprising fact about bamboo?

🌱 The general misconception with bamboo is that it is much more vulnerable than people realize. Bamboo doesn’t grow as fast as people think. While it of course is very resilient in its productivity in the sense that it rapidly grows again from a small shoot after it is cut down, it nevertheless takes roughly 7 years for it to be well-established and suitable for manufacturing sturdy products.

🎬 What actions can readers take now to support your cause?

We’re looking to fundraise 💰, as well as partner 🤝 with those who can take part in the forestry management system, including: logistics, the creation of bamboo strips, as well as downstream value-added products that are derived from our strips. Fundamentally, we need partners who can bring innovative bamboo products of all sorts of varieties, during both the processing as well as bringing them to market.

🦸🏻 What do you do when you’re not saving the world?

In my free time I like to spend time with my wife (happy wife = happy life 😉) and my 3 kids (aged 14, 12, and 7)!

🏄🏻♂️ I used to surf, and was really into free-diving during the pandemic, so I would love to do more of that again in my free time.

🎧 New Full Circle podcast episode!

🎉 Today, we’ve published our fourth podcast episode! In it, Karina interviewed Patti Chu of Mana Impact, an advisory which helps family offices direct their capital toward sustainable ventures, about why impact investing is so important and why it has been a hot topic recently.

🎧 Listen here!

⏭️ Next week, we’ll be discussing the role that electric vehicles are playing in Southeast Asia’s transportation sector transformation.

❓ Did you enjoy this week’s issue? If yes, please forward to your friends who would enjoy the read as well. Also, feel free to let us know what you thought by giving us feedback at [email protected].

🌊 SEA you next week!

Karina & Massimiliano